High-nickel anode material and Ultra high-nickel anode material’s Justice and outlook

High-nickel anode material

For a long time, nickel has been primarily used in coin production and the manufacturing of stainless steel. Nickel, due to its high chemical reactivity and ductility, has the advantage of increasing the driving range when its content is high.

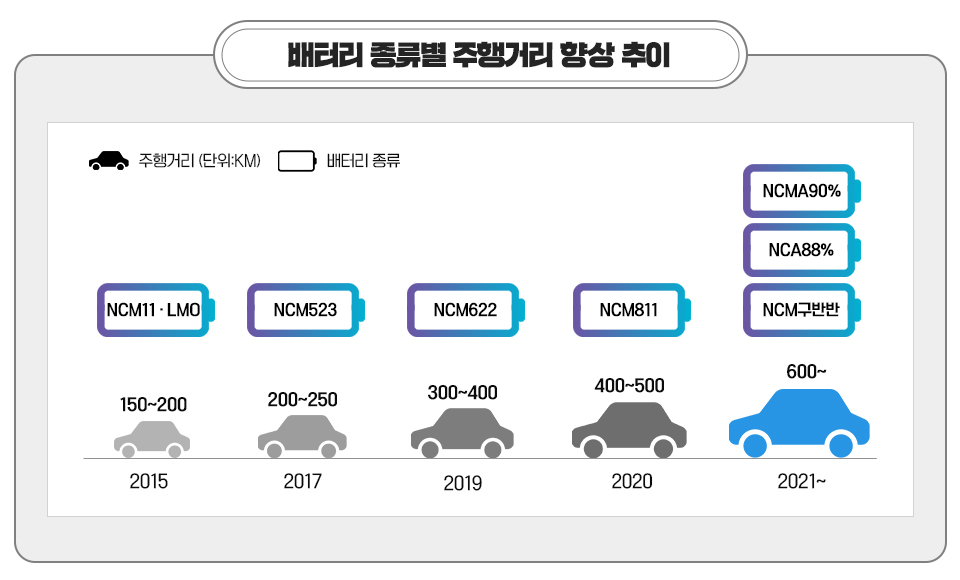

Using nickel in this way, batteries with significantly increased nickel content, ranging from 80% to 90%, are called high-nickel batteries. Nickel’s high energy density allows for longer driving ranges and the production of high-output electric vehicles with a single charge.

Batteries with higher nickel content are considered the future of electric vehicle batteries, and Korean battery companies are putting significant efforts into their development.

So, where is nickel primarily mined? The answer is Indonesia. Indonesia accounts for about 30% of the world’s nickel reserves. Korean battery companies are investing heavily in securing nickel mining rights in Indonesia to ensure a stable supply of this crucial resource and secure a leading position in the battery market.

However, just as a coin has two sides, the excessive use of nickel had its drawbacks. Due to safety concerns, nickel usage had to be carefully managed. Nickel, though highly efficient, can pose safety risks because it is prone to combustion once ignited. While each company is working to address these safety concerns, the precise solutions are still evolving and not yet clear.

It is suspected that a few years ago, fires involving South Korean cars like the Kona EV occurred for these reasons. To address the fire risk, measures were taken to regulate the battery charging capacity, limiting vehicle charging to below 90%.

Due to these safety concerns, there is also an opinion that, despite having a higher energy density compared to Chinese LFP batteries, Korean batteries ultimately achieve a similar level of energy density. The argument goes that even though Korean batteries have a higher energy density, if they are fully charged, there is a risk of fire, making it difficult to achieve full charging.

However, due to lessons learned from previous fire incidents and continuous improvements, it is now possible to charge these batteries up to 100%, making them more efficient compared to LFP batteries.

SK Innovation uses a zigzag pattern to wrap and separate the positive and negative electrodes, Samsung SDI employs special material and coating technology, and LG Energy Solution adds aluminum to enhance the battery’s stability.

LG Energy Solution is producing batteries with an 85% nickel content, which are planned to be used in GM’s Hummer. SK Innovation is manufacturing batteries with a 90% nickel content and is collaborating with Ford to produce the Ford F-150. Additionally, Samsung SDI is striving to produce batteries with an 88% nickel content for the production of BMW’s ‘iX.’

Ultra High-nickel anode material

There was news that Samsung SDI is developing the GEN6 battery model following the GEN5 battery model.

This model has a nickel content of around 91%, making it an ultra-high-nickel battery. Theoretically, using this battery, it should be possible to achieve a driving range of approximately 1,000 kilometers on a single charge.

The reason for advancing with ultra-high-nickel batteries is quite evident. Ultra-high-nickel batteries offer superior performance, and there has been some success in the development of high-nickel batteries.

Mass production has already begun, and the first company to use these batteries in electric vehicles will likely be Tesla.

As a potential solution to recent challenges in model performance and achievements, if Tesla incorporates NCMA ultra-high-nickel batteries, it could further advance its electric vehicles.

Tesla doesn’t exclusively use LFP batteries; they also use batteries from China, resulting in a mix of battery technologies. There have also been reports of Tesla producing their own batteries.

2 thoughts on “High-nickel anode material and Ultra high-nickel anode material’s Justice and outlook”